Hilti 3523418 Use and Care Manual Page 12

- Page / 17

- Table of contents

- TROUBLESHOOTING

- BOOKMARKS

Rated. / 5. Based on customer reviews

may become live, for example, when an electric cable

isdamagedaccidentally.Thispresentsaseriousrisk

of electric shock.

b) Concealed electric cables or gas and water pipes

present a serious hazard if damaged while you

are working. Accordingly, check the area in which

you are working beforehand (e.g. using a metal

detector). External metal parts of the power tool or

machine may become live, for example, when an

electric cable is damaged accidentally.

c) Check the power tool’s supply cord at regular in-

tervals and have it replaced by a qualified special-

ist if found to be damaged. Check extension cords

at regular intervals and replace them if found to

be damaged. Do not touch the supply cord or

extension cord if it is damaged while working.

Disconnect the mains plug from the power outlet.

Damaged supply cords or extension cords present a

risk of electric shock.

d) Dirty or dusty power tools which have been used

frequently for work on conductive materials

should be checked at regular intervals at a Hilti

Service Center. Under unfavorable circumstances,

dampness or dust adhering to the surface of

the power tool, especially dust from conductive

materials, may present a risk of electric shock.

e) Hold power tool by insulated gripping surfaces

when performing an operation where the fastener

may contact hidden wiring or its own cord. Fas-

teners contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give

the operator an electric shock.

f) When working outdoors with an electric tool

check to ensure that the tool is connected to the

electric supply by way of a ground fault circuit

interrupter (GFCI) with a rating of max. 30 mA

(tripping current). Use of a ground fault circuit

interrupter reduces the risk of electric shock.

g) Use of a ground fault circuit interrupter (GFCI)

with a maximum tripping current of 30 mA is

recommended.

h) Switch the power tool off and unplug the supply

cord in the event of a power failure or interruption

in the electric supply. This will prevent accidental

restarting when the electric power returns.

5.3.3 Work area

a) Ensure that the workplace is well ventilated. Ex-

posure to dust at a poorly ventilated workplace may

result in damage to the health.

b) Keep the workplace tidy. Objects which could

cause injury should be removed from the work-

ing area. Untidiness at the workplace can lead to

accidents.

c) If the work involves breaking right through, take

the appropriate safety measures at the opposite

side. Parts breaking away could fall out and / or fall

down and injure other persons.

d) Approval must be obtained from the site engineer

or architect prior to beginning the work. Work

on buildings and other structures may influence

the statics of the structure, especially when steel

reinforcing bars or load-bearing components are

cut through.

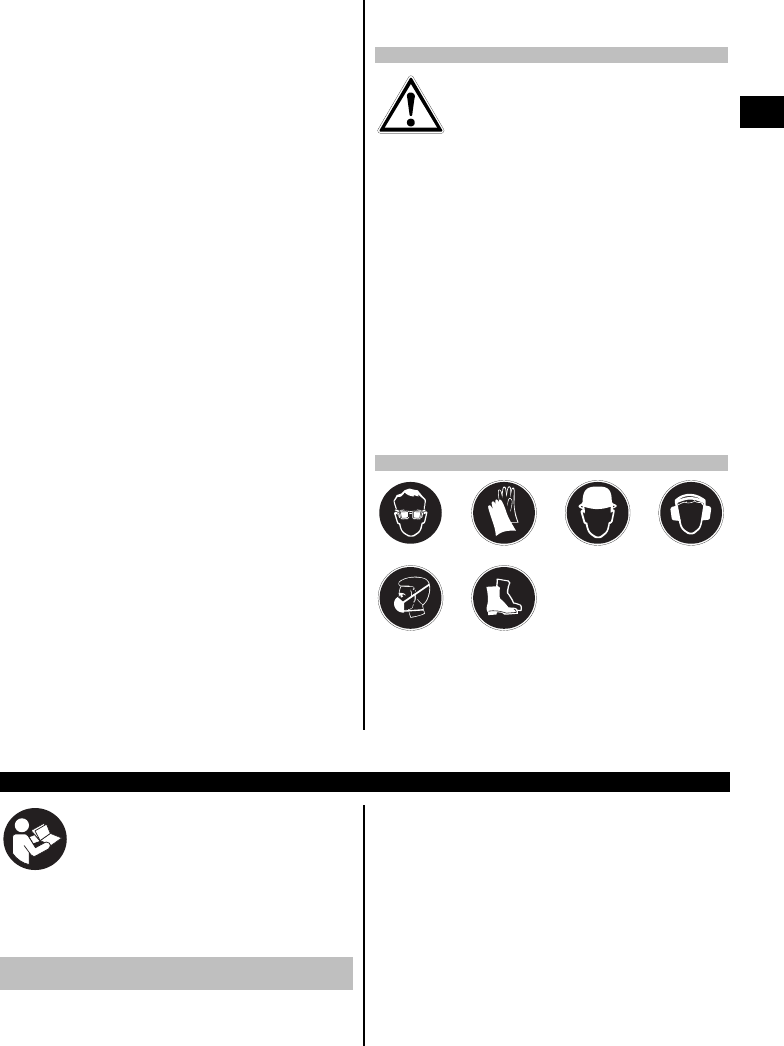

5.3.4 Personal protective equipment

The user and other persons in the vicinity must

wear ANSI Z87.1-approved eye protection, protective

gloves, a hard hat, ear protection, light respiratory

protection and safety footwear while the machine is

in use and during maintenance.

6Beforeuse

CAUTION

Check the insert tool for damage or uneven wear each

time before use.

6.1 Fitting, positioning and removing the side

handle (accessory) 2

1. Disconnect the mains plug from the power outlet.

2. Open the clamping band and push it on to the neck

of the tool.

3. Release the knob by turning it and then remove it.

4. Remove the hexagon-head bolt by pulling it out of

the grip unit.

5. Push the grip unit onto the mount on the clamping

band.

NOTE Check that the teeth are in the correct posi-

tion.

6. Reinsert the hexagon-head bolt.

7. Fit the knob.

8. Pivot the side grip into the desired position.

9. Secure the side grip by tightening the knob.

en

7

(14 pages)

(14 pages)

Comments to this Manuals